Mahim, Mumbai, Maharashtra

| Business Type | Manufacturer, Supplier |

| Material | Craft Paper |

| Industrial Use | Packaging |

| Feature | Anti-Curl, Heat Resistant, Waterpoof, Eco Friendly |

| Click to view more | |

Product Details

Product Discription:

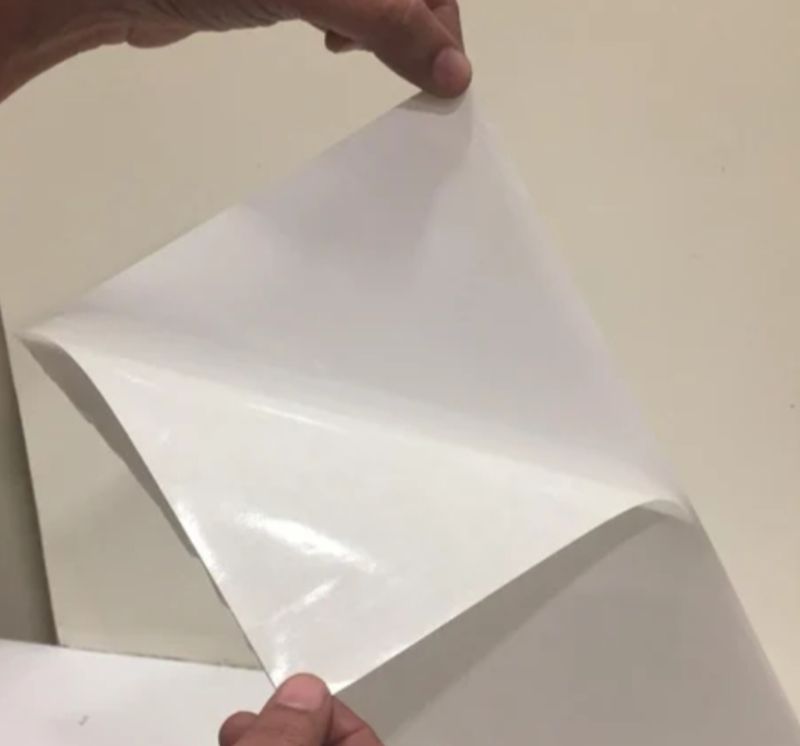

Poly-coated paper envelopes are used to protect sensitive items, such as documents, food items, and other products that need to be kept dry or shielded from moisture. The polyethylene coating enhances the paper's resistance to water, grease, and tears.

Specifications of Poly Coated Paper Envelopes:

-

Material Composition:

- Base Material: High-quality paper (commonly kraft, white, or other types of paper) coated with polyethylene (PE) or other plastic films.

- Polyethylene Coating: The coating layer can vary in thickness, typically from 10 to 50 microns, depending on the intended use.

-

Weight:

- The weight of poly-coated paper varies, but common ranges are between 80 to 300 GSM (grams per square meter), depending on the paper thickness and the level of coating applied.

-

Coating Thickness:

- The thickness of the polyethylene layer can vary between 10 microns to 50 microns, with thicker coatings offering better resistance to moisture and increased durability.

-

Finish:

- The surface finish of the envelope can be glossy or matte, depending on the intended aesthetic or functionality.

- Glossy finish provides a shiny look, often used for retail packaging.

- Matte finish provides a more subdued, non-reflective surface, often used for professional documents.

-

Strength:

- Poly-coated paper envelopes are highly resistant to tears, abrasions, and punctures.

- The polyethylene coating improves the tensile strength and durability of the paper, making it more resistant to breaking under pressure.

-

Moisture Resistance:

- The poly coating acts as a moisture barrier, ensuring the paper doesn’t absorb water, making the envelope resistant to humidity, rain, and other wet conditions.

- This property is especially important for applications like mailing food packaging or industrial products.

-

Customization:

- Printing: Poly-coated paper envelopes can be customized with high-quality printing, either on the paper side (for matte finish) or on the plastic-coated side (for glossy finish). Custom designs can be added for branding, marketing, or other purposes.

- Shape & Size: Available in a variety of shapes and sizes to suit specific applications, from standard letter-sized envelopes to larger packaging envelopes for shipping or industrial uses.

-

Sealing:

- Common sealing options include self-seal (peel and seal), flap seal, and glue-seal, depending on the use case.

-

Environmental Considerations:

- Poly-coated paper is often considered less eco-friendly compared to uncoated paper because of the polyethylene layer. However, there are more sustainable versions of poly-coated paper that use biodegradable or recyclable polyethylene or alternative coatings made from renewable materials.

Applications of Poly Coated Paper Envelopes:

- Shipping and Mailing: Provides protection to important documents or goods during transportation, especially in wet conditions.

- Food Packaging: Used for packaging items like take-out containers, fast food wrappers, and other food products that need a moisture barrier.

- Product Protection: Used for packaging products that are sensitive to moisture or need additional strength during handling.

Poly-coated paper envelopes offer a blend of paper’s versatility and the plastic layer's protective properties, making them ideal for many industries.

Looking for "120 GSM Poly Coated Paper" ?

Explore More Products