Mahim, Mumbai, Maharashtra

| Business Type | Manufacturer, Supplier |

| Pattern | Plain |

| Feature | Waterproof, Heat Resistant, Eco Friendly |

| Application | Used For Making Sachet for Tea, Coffee etc. |

| Click to view more | |

Product Details

Product Discription:

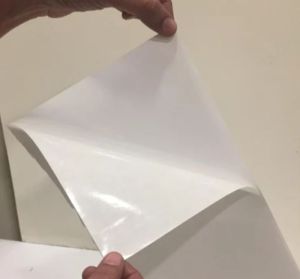

A sugar sachet is typically made from a type of poly-coated paper designed to hold sugar while offering durability and resistance to moisture. Here’s an overview of the specification and description of a sugar sachet poly-coated paper:

Material Composition:

- Base Paper: The base is made of paper, often wood pulp or a recycled fiber. This gives the sachet structure and rigidity.

- Poly Coating: A thin layer of polyethylene (PE) or other similar polymers is applied to one or both sides of the paper. The coating provides water resistance, durability, and a barrier to prevent moisture or air from affecting the sugar inside.

Specifications:

-

Thickness of Paper:

- Typically ranges from 40 gsm to 80 gsm (grams per square meter), with variations depending on the required strength and thickness for the application.

-

Poly Coating Weight:

- The polyethylene coating is usually very thin (around 10-20 microns) to maintain the sachet's flexibility while providing adequate moisture and air protection.

-

Sachet Size:

- Commonly, sugar sachets measure around 3g to 5g in weight, with dimensions usually being around 60 mm x 40 mm (for 3g sachets) or 70 mm x 50 mm (for 5g sachets). Custom sizes are available based on client needs.

-

Barrier Properties:

- Moisture Resistance: The poly coating prevents moisture from entering the sachet, ensuring the sugar remains dry and free-flowing.

- Oxygen Barrier: It also acts as a barrier to oxygen, which helps preserve the sugar’s quality.

-

Printability:

- Poly-coated paper can be easily printed on, allowing manufacturers to add logos, brand information, and product details. Printing is typically done using flexographic or rotogravure techniques.

-

Seal Type:

- Sugar sachets typically use a heat seal to close the sachet, where the poly-coated paper edges are fused together to form a secure, airtight seal.

-

Strength & Durability:

- The paper provides structure, while the poly-coating improves tear resistance and durability, ensuring the sachet doesn’t easily break open during transport or use.

-

Environmental Considerations:

- While the poly-coated paper provides moisture protection, it does make the sachet less environmentally friendly as it is harder to recycle due to the plastic coating. Some manufacturers are now exploring biodegradable alternatives or recyclable materials for eco-friendliness.

Applications:

Sugar sachets are commonly used in cafes, restaurants, and hotels, where single-use portions of sugar are needed. The poly-coated paper is essential in keeping the sugar fresh, dry, and easy to dispense, while also ensuring that the packaging withstands handling and environmental conditions.

Would you like more details on sourcing or specific manufacturers for poly-coated sugar sachets?

Looking for "Sugar Sachet Poly Coated Paper" ?

Explore More Products