Mahim, Mumbai, Maharashtra

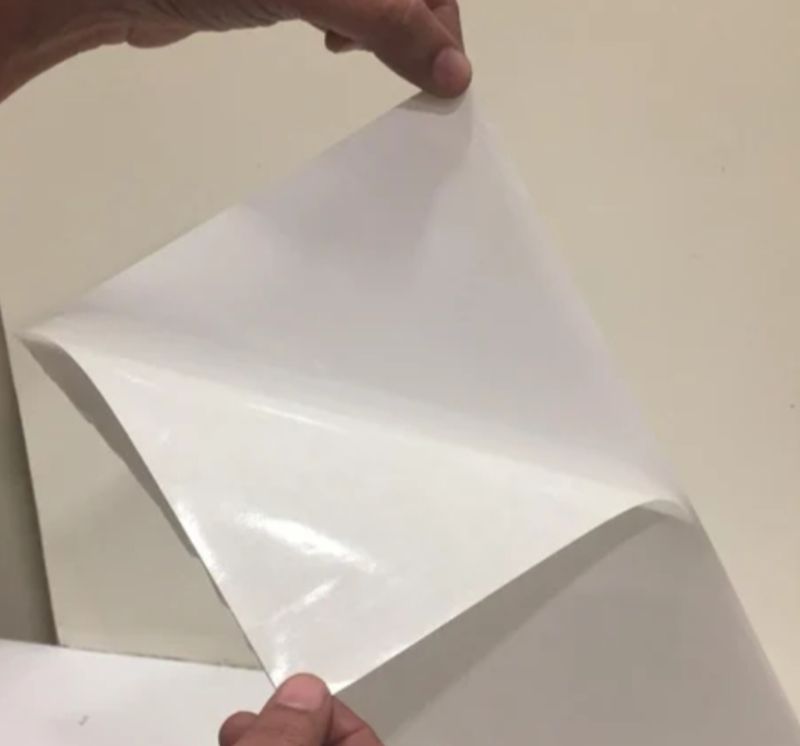

Poly Coated Paper

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Sugar Sachet Poly Coated Paper, 60 GSM PE Coated Paper and 120 GSM Poly Coated Paper from Mumbai.

| Business Type | Manufacturer, Supplier |

| Pattern | Plain |

| Feature | Waterproof, Heat Resistant, Eco Friendly |

| Application | Used For Making Sachet for Tea, Coffee etc. |

| Pulp Material | Mixed Pulp |

| Material | Craft Paper |

| Color | White |

| Thickness | 2-2.5mm |

| Country of Origin | India |

| Port | NA |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Product Discription:

A sugar sachet is typically made from a type of poly-coated paper designed to hold sugar while offering durability and resistance to moisture. Here’s an overview of the specification and description of a sugar sachet poly-coated paper:

Material Composition:

- Base Paper: The base is made of paper, often wood pulp or a recycled fiber. This gives the sachet structure and rigidity.

- Poly Coating: A thin layer of polyethylene (PE) or other similar polymers is applied to one or both sides of the paper. The coating provides water resistance, durability, and a barrier to prevent moisture or air from affecting the sugar inside.

Specifications:

-

Thickness of Paper:

- Typically ranges from 40 gsm to 80 gsm (grams per square meter), with variations depending on the required strength and thickness for the application.

-

Poly Coating Weight:

- The polyethylene coating is usually very thin (around 10-20 microns) to maintain the sachet's flexibility while providing adequate moisture and air protection.

-

Sachet Size:

- Commonly, sugar sachets measure around 3g to 5g in weight, with dimensions usually being around 60 mm x 40 mm (for 3g sachets) or 70 mm x 50 mm (for 5g sachets). Custom sizes are available based on client needs.

-

Barrier Properties:

- Moisture Resistance: The poly coating prevents moisture from entering the sachet, ensuring the sugar remains dry and free-flowing.

- Oxygen Barrier: It also acts as a barrier to oxygen, which helps preserve the sugar’s quality.

-

Printability:

- Poly-coated paper can be easily printed on, allowing manufacturers to add logos, brand information, and product details. Printing is typically done using flexographic or rotogravure techniques.

-

Seal Type:

- Sugar sachets typically use a heat seal to close the sachet, where the poly-coated paper edges are fused together to form a secure, airtight seal.

-

Strength & Durability:

- The paper provides structure, while the poly-coating improves tear resistance and durability, ensuring the sachet doesn’t easily break open during transport or use.

-

Environmental Considerations:

- While the poly-coated paper provides moisture protection, it does make the sachet less environmentally friendly as it is harder to recycle due to the plastic coating. Some manufacturers are now exploring biodegradable alternatives or recyclable materials for eco-friendliness.

Applications:

Sugar sachets are commonly used in cafes, restaurants, and hotels, where single-use portions of sugar are needed. The poly-coated paper is essential in keeping the sugar fresh, dry, and easy to dispense, while also ensuring that the packaging withstands handling and environmental conditions.

Would you like more details on sourcing or specific manufacturers for poly-coated sugar sachets?

| Business Type | Manufacturer, Supplier |

| Feature | Waterproof, Eco Friendly, Disposable, Durable |

| Industrial Use | Packaging |

| Pulp Material | Mixed Pulp |

| Material | Craft Paper |

| Packaging Type | Roll |

| Color | White |

| Country of Origin | India |

| Manufacturer | RK Enterprises |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Product Discription:

PE-coated paper (Polyethylene-coated paper) is paper that has been coated with a thin layer of polyethylene, which is a type of plastic. This coating makes the paper resistant to moisture, grease, and other substances, and it enhances the strength and durability of the paper. It is commonly used for food packaging, cups, and other products that require a water- or grease-resistant barrier.

Specification of PE Coated Paper:

-

Basis Weight (Weight per unit area):

- Typically ranges from 40 gsm to 350 gsm (grams per square meter).

- Lighter weights are often used for flexible packaging, while heavier weights are used for rigid packaging, such as cups.

-

Coating:

- The paper is coated with a single or double layer of polyethylene.

- PE coating can be on one or both sides, depending on the application.

- The coating adds to the moisture resistance, grease resistance, and durability of the paper.

-

Thickness:

- Thickness generally varies between 0.1 mm to 0.4 mm depending on the weight of the paper and the coating.

-

Color:

- Typically white, but can be produced in natural (brown kraft) or colored varieties.

- The color of the PE coating can be clear or opaque, depending on the desired final appearance.

-

Properties:

- Water Resistance: Effective at preventing water absorption, making it suitable for packaging wet products.

- Grease Resistance: Ideal for packaging oily or greasy foods like pizza boxes, snack wrappers, or fast food packaging.

- Strength: The coating helps increase the paper's tear and burst strength.

- Barrier Properties: Provides a barrier to gases and vapors, extending the shelf life of products.

- Printability: PE-coated papers can be printed on with inks and designs, which is great for branding and product labeling.

-

Environmental Considerations:

- Biodegradability: PE-coated paper is less biodegradable than uncoated paper because of the plastic coating. However, some developments are being made with biodegradable PE coatings.

- Recyclability: While recycling is possible, PE-coated paper is more difficult to recycle than uncoated paper due to the polyethylene layer, making it less eco-friendly. The recyclability also depends on the type of polyethylene used.

-

Applications:

- Food Packaging: Used for packaging items like sandwiches, burgers, wraps, and pastries.

- Beverage Cups: Commonly used for hot and cold beverage cups (coffee cups, drink cups).

- Fast Food Wrappers: Used in wrappers for burgers, fried foods, and other greasy foods.

- Ice Cream Cups: Also used for food containers where liquid or grease resistance is important.

- Takeaway Containers: For takeout packaging, offering protection against liquids.

PE Coated Paper vs. Other Coated Papers:

- Unlike wax-coated paper, PE-coated paper has superior resistance to moisture and is stronger in handling wet or greasy materials.

- Polypropylene (PP) coated paper is sometimes used as an alternative, though it’s not as commonly used in food packaging applications as PE-coated paper.

Would you like to see specific data or examples of products made with PE-coated paper?

| Business Type | Manufacturer, Supplier |

| Material | Craft Paper |

| Industrial Use | Packaging |

| Feature | Anti-Curl, Heat Resistant, Waterpoof, Eco Friendly |

| Pattern | Plain |

| Color | White |

| Thickness | 1-1.5mm |

| Country of Origin | India |

| Manufacturer By | RK Enterprises |

| Port | NA |

| Delivery Time | 5 DAYS |

| Packaging Details | Roll OFF |

Product Discription:

Poly-coated paper envelopes are used to protect sensitive items, such as documents, food items, and other products that need to be kept dry or shielded from moisture. The polyethylene coating enhances the paper's resistance to water, grease, and tears.

Specifications of Poly Coated Paper Envelopes:

-

Material Composition:

- Base Material: High-quality paper (commonly kraft, white, or other types of paper) coated with polyethylene (PE) or other plastic films.

- Polyethylene Coating: The coating layer can vary in thickness, typically from 10 to 50 microns, depending on the intended use.

-

Weight:

- The weight of poly-coated paper varies, but common ranges are between 80 to 300 GSM (grams per square meter), depending on the paper thickness and the level of coating applied.

-

Coating Thickness:

- The thickness of the polyethylene layer can vary between 10 microns to 50 microns, with thicker coatings offering better resistance to moisture and increased durability.

-

Finish:

- The surface finish of the envelope can be glossy or matte, depending on the intended aesthetic or functionality.

- Glossy finish provides a shiny look, often used for retail packaging.

- Matte finish provides a more subdued, non-reflective surface, often used for professional documents.

-

Strength:

- Poly-coated paper envelopes are highly resistant to tears, abrasions, and punctures.

- The polyethylene coating improves the tensile strength and durability of the paper, making it more resistant to breaking under pressure.

-

Moisture Resistance:

- The poly coating acts as a moisture barrier, ensuring the paper doesn’t absorb water, making the envelope resistant to humidity, rain, and other wet conditions.

- This property is especially important for applications like mailing food packaging or industrial products.

-

Customization:

- Printing: Poly-coated paper envelopes can be customized with high-quality printing, either on the paper side (for matte finish) or on the plastic-coated side (for glossy finish). Custom designs can be added for branding, marketing, or other purposes.

- Shape & Size: Available in a variety of shapes and sizes to suit specific applications, from standard letter-sized envelopes to larger packaging envelopes for shipping or industrial uses.

-

Sealing:

- Common sealing options include self-seal (peel and seal), flap seal, and glue-seal, depending on the use case.

-

Environmental Considerations:

- Poly-coated paper is often considered less eco-friendly compared to uncoated paper because of the polyethylene layer. However, there are more sustainable versions of poly-coated paper that use biodegradable or recyclable polyethylene or alternative coatings made from renewable materials.

Applications of Poly Coated Paper Envelopes:

- Shipping and Mailing: Provides protection to important documents or goods during transportation, especially in wet conditions.

- Food Packaging: Used for packaging items like take-out containers, fast food wrappers, and other food products that need a moisture barrier.

- Product Protection: Used for packaging products that are sensitive to moisture or need additional strength during handling.

Poly-coated paper envelopes offer a blend of paper’s versatility and the plastic layer's protective properties, making them ideal for many industries.